Membrane Bioreactor Advantages

Published on by Marina A, Previously Key Account and Content Manager at AquaSPE AG in Technology

Membrane bioreactor (MBR) is a wastewater treatment process which combines membranes with the biological process.

MBRs are widely used for municipal and industrial wastewater treatment.

They can treat up to 48 million liters of wastewater per day.

The combination of membrane filtration and a suspended growth bioreactor efficiently removes organic and suspended solids.

The MBR, unlike the conventional activated sludge (CAS) system, doesn’t use a secondary clarifier or a settling tank which would allow the solids to settle and separate them from the liquid. Instead, membranes are used for this purpose. This results in much better water quality.

MBRs were invented in the 1960s. Getting rid of the settling tank was extremely innovative, but the costs were high due to the high price of membranes, especially since the process would drastically become less effective due to membrane fouling. In 1989 the membranes were submerged in the bioreactor, which required two magnitudes lower of energy than before this breakthrough, lower flux but larger membrane area. Another advancement in MBRs was the introduction of two-phase bubbly flow to control fouling.

Bioreactor:

The bioreactor is any device or system which supports a biologically active environment.

They can be aerobic or anaerobic.

Bioreactors are classified in two groups:

- suspended growth bioreactors

- biofilm bireactors

Membranes:

Membranes are two-dimensional screens used for physical separation of the particles from the liquid.

The membranes are used for liquid-solid separation. They can be semi-permeable or perm-selective which means they allow only some particles to go through them or even select which particles are allowed to pass. The membranes can be for microfiltration or ultrafiltration, depending on the size of the particles they allow to go through them.

There are 5 types of membrane configuration for MBRs:

- hollow fibre

- spiral wound

- plate and frame

- pleated filter cartridge

- tubular

The membranes do not allow the solids made by the biological process to go through along with the water.

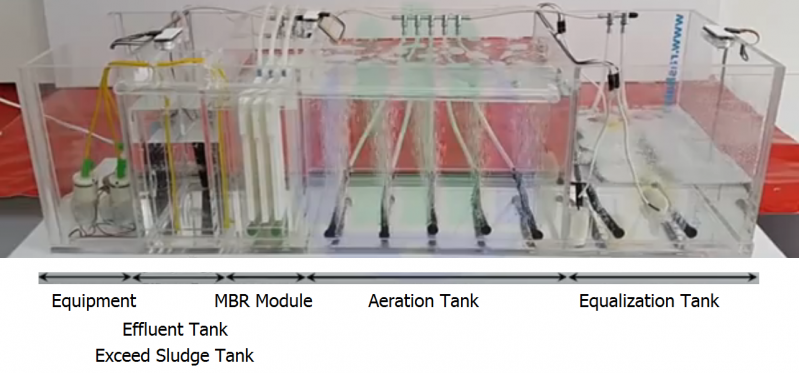

Image: Micro-Model for MBR Wastewater Treatment Plant

Image Source: Rasahb Tarh video on YouTube, youtube.com/watch?v=ifYQ36SvMtE

Advantages:

- High quality effluent – the water, after being treated in the MBR is of extremely high quality since all the biomatter, solids and microorganisms are filtered. The effluent is directly reusable or recyclable and can be release in the environment.

- Independent HRT and SRT – sludge retention time (SRT) and hydraulic retention time (HRT) are completely independent since sludge solids are completely retained in the bioreactor, unlike in CAS where the biomass needs to be flocs into flocs which then need to settle so the settlebility relates to the retention of the liquid.

- Small footprint – MRS require 50% less space in comparison to classical activated sludge (no clarifiers are needed and nor pre-treatment nor tertiary treatment are needed, there are less pipes and valves, less equipment). MBRs also reduce the activated sludge treatment footprint by removing part of the liquid component of the mixed liquor. The concentrated waste is then treated in the activated sludge process.

- Consistent performance – mixed liquor suspended solids (MLSS), the organic content in the water, can be much higher than in CAS. Higher biomass concentration results in effective removal of biodegradable materials.

- Low sludge production – less sludge is produced and needs to be disposed less frequently than in CAS.

- Less sludge dewatering – the sludge contains a high solid content.

Disadvantages:

- High capital and operational costs. However, recent economic analysis show their costs are similar to classical processes.

- Operational complexity – they require trained personnel

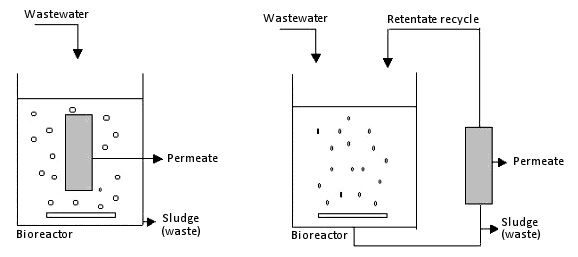

There are two types of MBRs:

- internal/submerged – membranes are immersed or integrated in the bioreactor

- external/sidestream – membranes are a separate unit.

Image: Configuration of MBR systems: submerged on the left and lateral flow on the right

Image source: Pombo, cdn.intechopen.com/pdfs-wm/16301.pdf

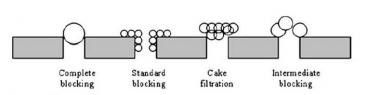

Membrane fouling, clogging and cleaning:

With time, the membrane performace decreases due to fouling, i.e. deposition of particles on the membrane. This results in increase hydraulic resistance and means membranes need cleaning.

Image: Fouling mechanisms. Source: RADJENOVIC et al. (2008)

The main causes of membrane fouling are:

- Adsorption of macromolecular

- Growth of biofilms on the membrane surface

- Precipitation of inorganic matter

- Aging of the membrane

Membrane cleaning can be physical or chemical.

Physical cleaning is usually done by backwashing – reverse flow through the membrane, which may be enhanced by air bubbles. It removes ‘reversible’ or ‘temporary’ fouling.

Chemical cleaning uses sodium hypochlorite, an oxidizing agent, combined with mineral or organic acids. It removes ‘irreversible’ or ‘permanent’ fouling.

Chemically-enhanced backflush combines backwashing and chemical cleaning.

Physical cleaning is faster and doesn’t degrade the membrane but chemical cleaning will be required periodically nevertheless.

Chemical cleaning can be done every 6 months or on shorter periods when the trans-membrane pressure has increased for 5 kPa compared to the initial pressure, which indicates clogging.

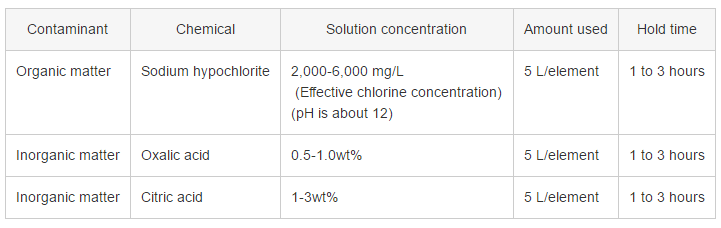

The chemicals used for cleaning depend on the contaminant:

Table source: toraywater.com/services/cleaning/cle_003.html

Coarse bubble aeration in MBRs produces mixing and inhibits fouling.

Aeration is crucial for both hydraulic and biological performance.

Air diffusers are fixed at the bottom of the aeration tank. Bubbles rapidly rise from the bottom and suspend the solids and keep them from settling. Additionally, the air bubbles supply the biomass with oxygen which enhances biodegradation.

Sources:

Media

Taxonomy

- Membrane Bioreactor Systems

- Waste Water Treatments

- Membranes

- Wastewater Treatment

- Water Treatment Systems

- Waste Water Treatment