Filamentous Bacteria - Problems and Solutions

Published on by Marina A, Previously Key Account and Content Manager at AquaSPE AG in Maintenance

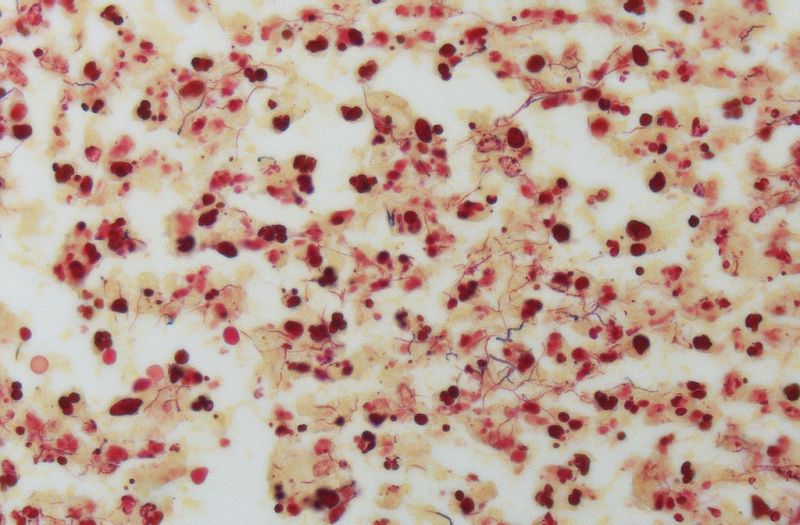

Filamentation is the abnormal growth of some bacteria in which cells do not separate but elongate and have multiple chromosomal copies. They grow in long thread-like strands.

The causes of bacterial filamentation are:

- A response to DNA damage

- Nutritional changes.

The presence of some filamentous bacteria is benefitial in floc formation to a biomass.

The filaments connect to each other and form a mesh that is crucial for floc formation.

Filamentous bacteria serve as a base of the structure on which other bacteria can attach and form flocs which are important in flocculation and settling.

However, excessive amount of the filamentous bacteria in wastewater may cause problems with sludge settling (bulking and foaming) and have impact on wastewater treatment efficiency.

Excessive filamentous microorganisms will appear due to:

Little sludge load - filamentous microorganisms attain high growth rates despite low substrate and oxygen levels,

Lopsided composition of wastewater – in industrial firms and variations in effluent,

Variations in the wastewater - varying flow or temperatures, changes in nutrients…

Foaming and sludge bulking negatively affect the water treatment plant cleaning process and the first step in getting rid of them, e.g. controlling filamentous bacteria growth is to identify the filaments.

Depending on the nutrients, different filamentous bacteria will dominate in wastewater. The most common are the Gram Stain and the Neisser Stain.

Identifying filamentous bacteria is time-consuming and not easy. The Document Filamentous Bacteria Identification & Process Control may help you simplify the process.

Bulking sludge happens due to bad settling and thickening of the solids. Uncontrolled growth of filamentous bacteria influences settling of activated sludge. Bulking sludge has a sludge volume index (SVI) above 150 ml/g (normal SVI=100 ml/g)

The reason behind the unstoppable filamentous growth is usually the hydrophobic surface of bacteria, which leads to flotation of the sludge.

Since a certain amount of filamentous bacteria is useful in the activated sludge process, lack of it may cause flocs with good settling abilities but which leave behind a turbid effluent. This is because filaments are a backbone of a floc structure and a base for larger flocs and some filaments also “catch” small particles during settling, therefore, lowering the effluent turbidity. Too many filaments will, on the other hand, cause bulking.

Depending on the type of filaments, two forms in sludge settling can be present:

interfloc-bridging – filaments extend from the floc surface and physically hold the floc particles apart

open-floc structure - where the filaments grow mostly within the floc and the floc grows around and attached to the filaments.

There are 6 environment conditions and causes of filament overgrowth in activated sludge and 4 of these are present in municipal wastewater systems while all of them occur in industrial wastewater systems and low nutrients and low pH are specific only for industrial wastewater systems.

Cause | Filament |

Low Dissolved Oxygen Concentration | Sphaerotilus natans |

Low F/M | type 0041 |

Septicity | type 021N |

Grease and Oil | Nocardia spp. |

Nutrient Deficiency |

|

Nitrogen: | type 021N |

Phosphorus: | Nostocoida limicola III |

Low pH | fungi |

Table source Activated Sludge Microbiology Problems and Their Control

The foam floats and accumulates on the surface and decreases the effluent quality and control of sludge retention time (SRT).

There are 3 filamentous organisms which cause activated sludge foaming.

Foam Description | Cause(s) |

thin, white to grey foam | low cell residence time or "young" sludge (startup foam) |

white, frothy, billowing foam | once common due to nonbiodegradable detergents (now uncommon) |

pumice-like, grey foam (ashing) | excessive fines recycle from other processes (e.g. anaerobic digesters) |

thick sludge blanket on the final clarifier(s) | denitrification |

thick, pasty or slimy, greyish foam (industrial systems only) | nutrient-deficient foam; foam consists of polysaccharide material released from the floc |

thick, brown, stable foam enriched in filaments | filament-induced foaming, caused by Nocardia, Microthrix or type 1863 |

Table source Activated Sludge Microbiology Problems and Their Control

Solutions to sludge bulking:

Sludge Juggling

Sludge juggling is a short-term solution to bulking which involves return sludge (RAS) flow rate and waste feed points manipulation.

Solids must be removed from the final clarifier faster than they are added so the RAS flow rate must be increased. This increase is limited because the increased return flow to the system hydraulically pushes more sludge from the clarifier, making effluent TSS losses worse.

Polymer and Coagulant Addition

There are different types of chemicals which can be added to enhance activated sludge settling. They are usually added to the MLSS as it leaves the aeration basin or to the secondary clarifier center well.

Chlorination

Chlorine and hydrogen peroxide successful temporary control method for filamentous growth.

Chlorine is cheap and available on-site at most plants so it is widely used. Sufficient chlorine damages the filaments extending from the floc surface while leaving organisms within the floc largely untouched. (If the bulking problem is not caused by filamentous bacteria, adding chlorine can worsen the bulking – for slime bulking or poor floc development)

It is crucial to properly dose the chlorine and add it frequently to activated sludge. To find the right dose, one should start with smaller doses and increase them gradually. When the correct dose is added, the sludge settleability improves within 3 days.

Long term measures include activities such as: control of influent waste septicity (organic acids and H2S); nutrient additions (industrial waste systems only); changes in aeration; and changes in biomass concentration or changes in waste feeding pattern.

Sources:

Media

Taxonomy

- Bacteria

- Industrial Wastewater Treatment

- Sludge Treatment

- Sludge Management

- Waste Water Treatments

- Wastewater Treatment

- Sludge Treatment & Management

5 Comments

-

Filaments are the normal growth form of a variety of species and not abnormalities. Jenkins, Richard and Daigger are the best resources in my opinion. There are a variety of ways to discourage filaments, improve settling, and control foam. The charts presented are useful but the overall article is oversimplified.

-

I fully concur with Gerd regarding the two other comments below his'. The wording "comment" is still a too nice word.

-

Marina, a nice sum up of the problems and options to solve. The comments below don't make much sense in my opinion and for sure are not helpful to solve the matter.

-

A post to not say hello and Yes yet. Filamentous bacteria. Not only does not exist but more people arrive to explain the inexplicable when simply it is a conglomerate of hair, hair, son of textiles, vegetable filament. Describes this phenomenon as if it was a function of treatment in wastewater management descriptions.

A bacterium is always looking to support and perpetuate. This support be mineral or vegetable. The conglomerate of filament is only used for net trapping dead bacteria.

-

Dear future leader of our messed up world. In case your educational background did not take the time to explain "Parameters" this may be of some assistance to you. The chlorine used is the direct cause of your filament bacteria. All microbes work as a team effort to carry on bio degradation functions. Once you kill the microbes that live in the vulnerable ph range this allows the bacteria that exists out side of the ph range to thrive. According to the listed solutions "Add more chlorine". ??? As a lifelong student of logic I had to stop and scratch my head on that answer. So many of our youngest and brightest scientists are missing basic life sciences and have been trained NOT to think for themselves. Just as in chess. pawns can not kill the king. Chlorine can not kill all microbes regardless of the concentration. The very use of chlorine is allowing new virulent microbes to exceed of scientific community's ability to find cures.

2 Comment replies

-

Please educate me then on First what would be your solution then. But more imporatantly Um if i have not introduced chlorine into my system and i have a Filamenteous bacteria problem due to my Low D.O. "dissolved oxygen levels being to low how can u possiably make a statement that my problem is due to chlorine. Dear future Leaders of the world do not listen to this uneducated man. I would use chlorine as an OPTION to fix my filemeteous that was cause dby LOW D.O. NOT chlorine. For anyone wanting to comment on something please do your research before u run off with the mouth. Prime example Guy you can checkmate a king with a pawn my uneducated student.

-

Somewhat helpfull. New to the waste water side. 20 years on the water side. Trying ro obtain knowledge.

Pawns can mate a King.

-